Polybutylene adipate terephthalate/PBATCAS:55231-08-8

Other name:1,4-Benzenedicarboxylic acid, 1,4-dimethyl ester, polymer with 1,4-butanediol and hexanedioic acid

Polybutylene adipate terephthalate/PBAT CAS:55231-08-8 Introduction:

PBAT (polybutylene adipate/terephthalate) is a thermoplastic biodegradable plastic made from the copolymerization of adipic acid, terephthalic acid and butanediol. It has both the degradability of aliphatic polyesters and the mechanical properties of aromatic polyesters13. Its properties include excellent ductility (high elongation at break), heat resistance (melting point of about 115-130°C) and processability (similar to LDPE, can be blow molded and cast into film)14. At the same time, it can be completely degraded into water and carbon dioxide by microbial action in the natural environment, meeting international standards. The product is mostly in the form of milky white particles, which are widely used in packaging bags, agricultural mulch films, disposable tableware and other fields. It is one of the most mature biodegradable materials in the current market.

PBAT has the following characteristics and advantages:

1. Biodegradability: PBAT can be gradually degraded in the natural environment through the action of microbial enzymes, and ultimately decomposed into reusable substances such as carbon dioxide, water, and biomass. This makes PBAT an environmentally friendly alternative material.

2. Renewable: PBAT can be synthesized using renewable raw materials such as vegetable oil and starch, reducing dependence on fossil fuels.

3. Physical properties: PBAT has good flexibility, impact resistance, and heat resistance, and can be used in various application fields such as manufacturing films, packaging materials, textiles, and injection molded parts.

4. Compatibility: PBAT can be blended with other polymers (such as polylactic acid PLA) to improve the performance and functionality of the material.

5. Widely used: PBAT is widely used in the packaging industry, such as food packaging bags, garbage bags, agricultural films, etc. It can also be used in fields such as textiles, consumer goods, and medical supplies.

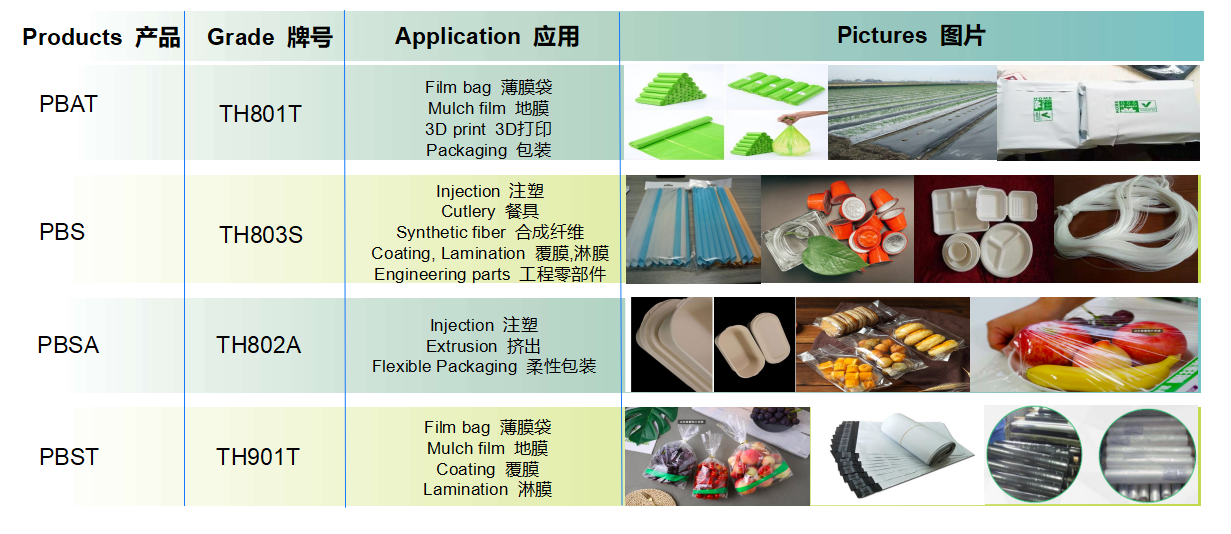

Polybutylene adipate terephthalate/PBAT CAS:55231-08-8 Application

PBAT (polybutylene adipate/terephthalate) is a biodegradable and environmentally friendly material, mainly used to replace traditional plastics. Common uses include: shopping bags, express packaging films, disposable tableware and other daily packaging; agricultural mulch films, seedling pots and other agricultural covering materials; and garbage bags, diaper back films and other sanitary products. Its flexibility and composting degradation characteristics (complete decomposition in 3-6 months) make it a mainstream solution under the "plastic ban" policy.